Veröffentlichungen

Hier finden Sie ausgewählte Publikationen, Konferenzbeiträge und Standards aus dem Umfeld der Imprintec i3D®-Technologie.

Überblick

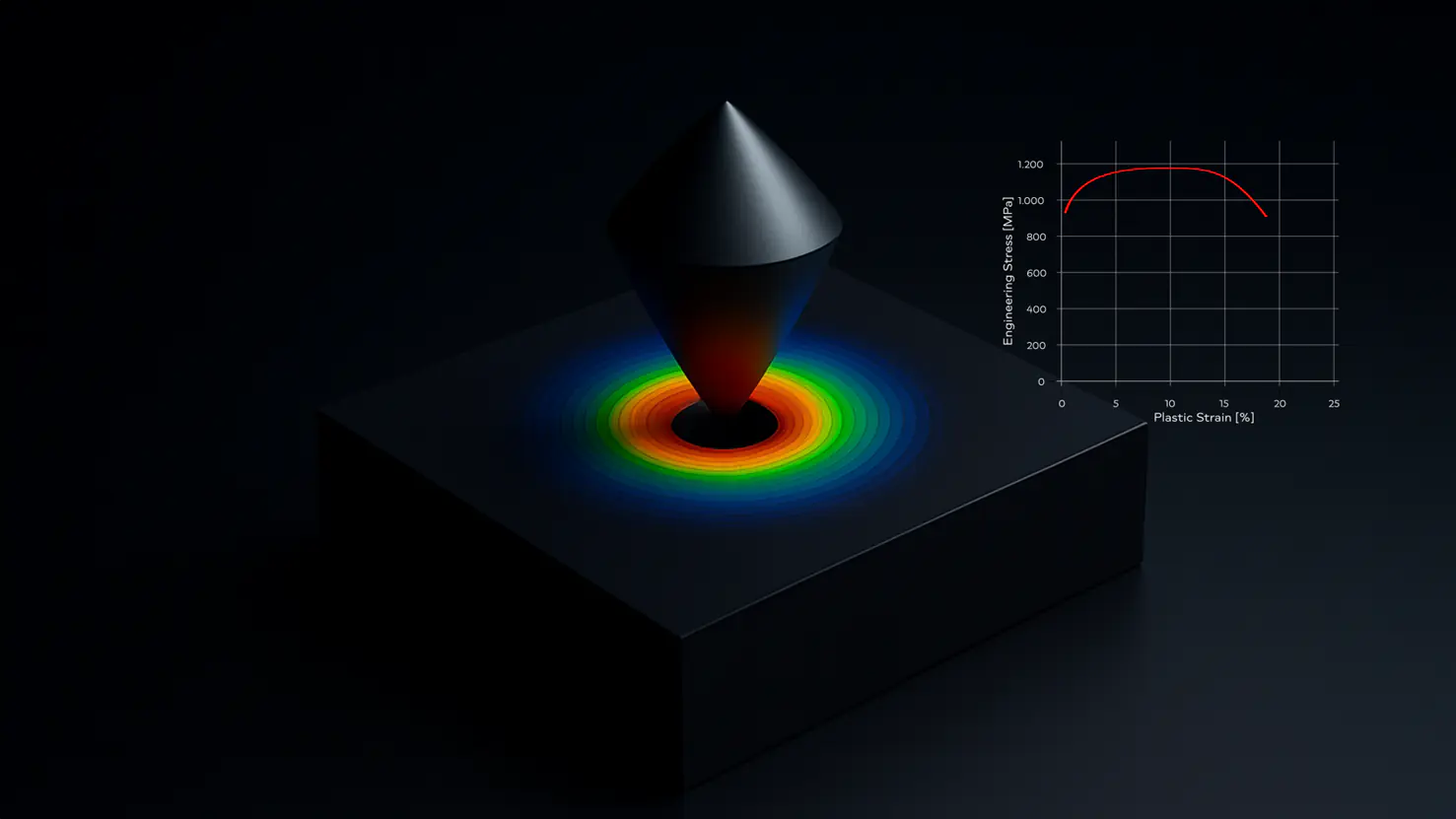

ASTM E3499-25 (2025) — Standard Test Method for Indentation Plastometry of Metallic Materials

Neue ASTM-Veröffentlichung aus 2025.

Significance and Use

5.1 The indentation plastometry test can provide stress-strain curves that are comparable with those obtained from conventional tension testing.

5.2 Evaluation of the mechanical properties such as yield strength, tensile strength, and uniform elongation at necking is important throughout the lifecycle of metallic components. This includes during product development, in production for quality assurance and quality control, during service to inform repair strategies, planning preventative maintenance, and assessing residual lifetime, and after a component’s service life, to determine the root cause of a component failure. Established test method standards exist for measuring these mechanical properties, but these methods require large volumes of test material and the test specimen to be machined into a specific geometry, and result in the destruction of the component and test specimen.

5.3 The requirement to determine mechanical properties from a localized region, without the need to extract a test specimen, led to the development of indentation plastometry (1, 2).4 As an indentation-based test method, it can be used as a high-throughput test method to screen mechanical properties of metallic materials, and the mechanical properties can be mapped across a component (3). In addition, the test can allow for components that are in service to be tested in situ.

5.4 The indentation plastometry test method has some similarities with hardness testing (for which standards exist, for example Brinell or Vickers hardness), as it involves pushing a hard indenter into the surface of a material and measuring characteristics of the permanent indentation left after removal of the force. However, this method, by measuring the residual indentation geometry, not just the diameter, and combining it with inverse finite element analysis, allows for the extraction of yield strength and tensile strength values comparable with those obtained from conventional tension testing.

5.5 Fundamental Assumptions:

5.5.1 Tension-compression symmetry—The indentation plastometry test method utilizes a finite element model with the von Mises yield criterion to describe the plastic behavior of the specimen. This criterion assumes that the true stress-strain curve is the same in tension and compression. This assumption is appropriate for most metals, with some exceptions. Some exceptions include: metals with strong crystallographic texture and hexagonal close packed (HCP) crystal structure (4), cast irons, some nanocrystalline materials, and nickel-based superalloys that are directionally solidified or have strong crystallographic texture. Therefore, indentation plastometry can generally be used to determine properties comparable to those in a tension test.

5.5.2 Fracture—The indentation plastometry test does not probe the fracture properties of metallic materials and therefore cannot be used to determine the elongation at fracture. For brittle materials which fracture in a tension test before reaching the uniform elongation at necking, the indentation plastometry test will overestimate the tensile strength.

5.5.3 Plasticity law—Selection of an appropriate plasticity law for the material being tested is fundamental to the performance of the indentation plastometry test. The recommended constitutive plasticity laws (described in 7.5) limit the applicability to materials that have monotonic hardening behavior (Note 7).

5.5.4 Anisotropy—The indentation plastometry test method is not appropriate for materials with high anisotropy in the plane of the material being tested. 9.3.3.3 describes how to classify the amount of anisotropy to determine if the method is not appropriate for the plane being tested.

Scope

1.1 This test method covers procedures for carrying out indentation plastometry, an indentation-based test technique to determine the plastic stress-strain properties of metallic materials, including yield strength, tensile strength and uniform elongation at necking, using inverse finite element analysis.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Zur ASTM E3499-25RISØ 2024 – IOP Conf. Series (2024)

"Influence of printing parameters on part density in L-BPF of Ti-6Al-4V and correlation with static mechanical properties measured using indentation testing"

#RISO2024 | RISØ 2024 - IOP Conf. Series: Materials Science and Engineering 1310 (2024) 012030 - IOP Publishing

J Schulz(1), E C Santos(1), A Kalliath(2), B Schmaling(2), P Zok(2), S Siegert(2), I S Dandu(2), KH Lindner(2), E Bruder(3) and K Durst(3) | (1) IQS, Carl Zeiss IMT GmbH, Oberkochen, Germany; (2) Imprintec GmbH, Bochum, Germany; (3) Department of Physical Metallurgy, TU Darmstadt, Germany

Abstract. A complete workflow of parameter development and process qualification of a part manufactured using laser powder bed fusion (L-PBF) AM technique requires data of porosity, pore morphology, distortion and static mechanical properties. Using a combination of two non-destructive techniques: Computed tomography and indentation testing, the influence of printing parameters on defect types and part density in L-PBF of Ti-6Al-4V is described. In addition, the results using the combined method are compared to conventional testing methods.

Zum PaperMetals and Materials International (2022)

"Effect of Pulse Current GMAW on the Yield Stress of the S460M TMCP Steel Welded Joints"

#MMI | 2022-07 | Metals and Materials International

A. Zavdoveev, P. Zok, V. Pozniakov, M. Rogante, T. Baudin, M. Heaton, A. Gaivoronskiy, S. Zhdanov, P. Acquier, T. Solomijchuk, V. Kostin, M. Skoryk, I. Klochkov & S. Motrunich

Abstract: "Thermomechanically cold processed (TMCP) steels with a high level of strength are actively used in various constructions. The high strength of the TMCP steels is acquired due to the formation of the fine-grained structure. Such steels have relatively low carbon percentage. These greatly simplify the solution of the problem of improving the quality and reliability of metal structures. At the same time this raises new questions in terms of the technology for welding such steels. In the first instance, it is conditioned by the complex behavior of the TMCP structure under the welding thermal cycle effect. The most important property of the welded joint is yield stress (YS) which characterizes the workability of the whole joint. The estimation of the YS while developing the welding technology is a valuable task for design. This current research has made a complex investigation of the modern welding technique's effect on the behavior of the yield stress formation in TMCP steel welded joints. For progressive technology development, pulse arc welding was used."

Zum PaperConference Paper (2019)

"Fine-grained low carbon bainitic steels with improved properties."

#HRPZBS | 2019-07 | Conference Paper on ResearchGate H. Roelofs, P. Zok, B. Schmaling

Abstract: "Reducing the weight of car components has led to more filigree parts over the last decade and the use of stronger materials. Conventional solutions with quenched and tempered steels not always fulfil the demands concerning technical reliability, economics and environmental friendliness. Thermomechanically processed and continuously cooled bainitic steels are clearly better for demanding applications balancing these material's aspects which has led to a successful introduction of new steel grades into car components during the last decade. However, bainitic steels often do not reach the high Charpy impact toughness values of quenched and tempered steels. This is in particular true at sub-zero temperatures and after thermal or thermo-chemical treatments. Applying innovative technologies, the above mentioned handicap of bainitic steels can be reduced or completely eliminated by refinement of the prior austenite grain sizes (not only in flat products but also in long products). In the present work the industrial production technology "XTP" was applied to produce fine-grained low carbon bainitic-martensitic steel bars. In comparison with conventionally hot rolled bars the Charpy transition temperature then was decreased by ~60°C. The influence of a tempering treatment on mechanical characteristics was investigated in detail and will be discussed. Results demonstrate significant improvements in comparison with conventionally produced bars. The unique property combinations found in these new products open new perspectives for them in challenging applications."

Zum PaperDIN SPEC 4864 (2019)

"DIN SPEC 4864"

#DS4864 | 2019-11 | Technische Regel im Beuth Verlag A. Braun, T. Chudoba, M. Griepentrog, M. Schäfer, B. Hachmann, B. Schmaling, P. Zok, P. Beisel, P. Reinstädt, F. Menelao

Einführungsbeitrag: "Diese DIN SPEC wurde im Zuge des PAS-Verfahrens durch ein DIN SPEC (PAS)-Konsortium (temporäres Gremium) erarbeitet. Die Erarbeitung und Verabschiedung dieser DIN SPEC (PAS) erfolgte durch die im Vorwort genannten Verfasser. Dieses Dokument legt ein Prüfverfahren zur Bestimmung von Fließkurven von metallischen Werkstoffen mittels zerstörungsarmem Prüfeindruck, 3D-Vermessung und Finite-Elemente-Werkstoffmodell fest. Die Fließkurven dienen zur Ermittlung von Vergleichskennwerten zu Kennwerten aus dem Zugversuch nach DIN EN ISO 6892-1. Dieses Verfahren gilt für Werkstoffe: - die sich plastisch verformen, - die beim Eindringen des Prüfkörpers einen Aufwurf im Randbereich des Prüfeindrucks erzeugen, - dessen Korngröße maximal 1/3 des Eindruckdurchmessers beträgt und - welche kein Lamellengraphit/Kugelgraphit/hohe Porosität oder Gefügebestandteile enthalten, die einen Festigkeitsunterschied in Zug und Druck bewirken. Das Verfahren kann durch eine werkstoff- und probenspezifische Anpassung (Kalibrierung) ergänzt werden. Das Verfahren liefert quantitative richtungsunabhängige Ergebnisse. Bei geringer Eindringtiefe kann das Verfahren qualitativ zur Beurteilung von richtungsabhängigen Fließkurven und Vergleichskennwerten genutzt werden."

Zur DIN SPEC 4864